Fermilab is helping extend the life of paved surfaces. By cross-linking modified bitumen or other binders, mobile, truck-mounted electron accelerators could transform a newly constructed paved surface into a tough, long-lasting material, significantly extending the life of public roads and airport runways.

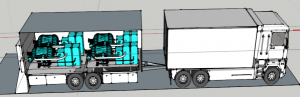

There are several opportunities under the pavement and coatings initiative that may be enabled by the use of accelerator technology to transform materials. These include special purpose coatings, such as anti-skid, corrosion resistant, or chemically resistant coatings, and thick-film coatings for a variety of industrial applications. Increasing pavement life using a mobile, compact SRF accelerator is of significant interest because of the potential economic and environmental impact.

The U.S. spends more than $50 billion per year to grind off and replace bitumen-based asphalt. Even a small extension of service lifetime can have enormous economic benefits. High-power mobile accelerators enable entirely new construction techniques based on in-situ crosslinking that can alter the properties of materials after they are put in place.

Through an Interagency Agreement between the U.S. Army Engineer Research and Development Center (ERDC) and the U.S. Department of Energy, IARC is currently working with ERDC to develop the advanced materials and accelerator technologies that will improve the strength, weather resistance, toughness, chemical resistance and service life of paved surfaces.